XsunX CIGSolar™ Thermal Evaporation System:

Project Graphics and Build Updates 6/1/12

Above: CIGSolar™ Heat Test Process

This CIGSolar™ tool build update provides a significant milestone in our project. Recent acceptance testing with the system heated and under vacuum passed without a hitch. The picture to the left shows zones in our system heated to 650 degrees centigrade while also under vacuum.

With the testing of the vacuum, heat, and material transport systems completed we have now moved toward disassembling and preparing the system for shipment.

Above: CIGSolar™ Components Prepared for Shipment

With the system being disassembled it’s easy for us to point out a few nice features of the CIGSolar™ tool.

In the picture to the right you can see several shrink wrapped pallets. These are the material transport and heating systems that were designed as integrated “packs”. This design feature makes the system easier to assemble or remove for servicing. You can also have replacement “packs” ready to install to reduce service time.

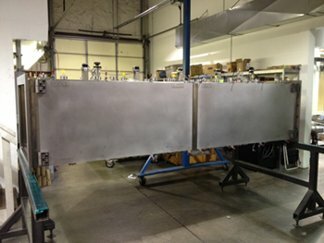

Above: Main CIGSolar™ Process Chamber Prepping for Shipment

Another important design feature of the CIGSolar™ tool was aimed at reducing the complexity, cost, and manufacturing floor area required for thermal evaporation.

Unlike some systems that break each of the CIGS process zones into separate costly vacuum chamber systems, the central CIGSolar™ processing chamber, shown to the left, provides the complete processing environment in one chamber helping to reduce assembly costs and factory floor space.