Our CIGSolar® system design, incorporating patent pending technology, focuses on producing high conversion efficiency, low cost thin-film CIGS absorber, which utilizes a multi-area thermal deposition process to minimize processing defects to create uniform CIGS films.

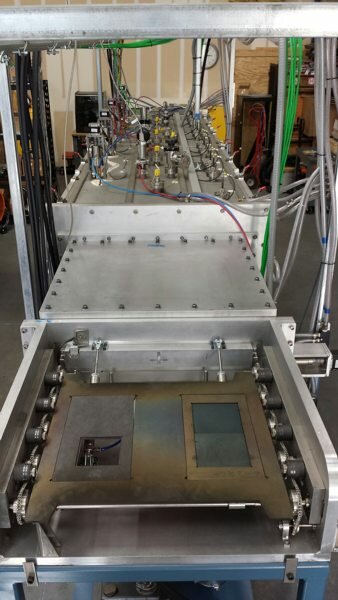

The proprietary manufacturing process design utilizes our CIGSolar® thermal co-evaporation process coupled with aqueous CdS deposition and metallization on sputter-prepared 156 mm square flexible stainless steel substrates in a continuous batch-processing format to produce CIGS solar cells. Utilizing the thermal co-evaporation process, we have already achieved NREL verified 16.36% efficiency conversion helping to support CIGS viability as an alternative long-term technology investment.

There are no pre or post selenization or annealing process requirements.

The manufactured cells are non-toxic and ready for use once tested and binned. Each production CIGSolar® co-evaporator will be rated to process approximately 400 substrates per hour. When you need more capacity, you add additional evaporators and scale support equipment to match. This allows for an incremental ramp-up and an opportunity to lower initial start-up costs.

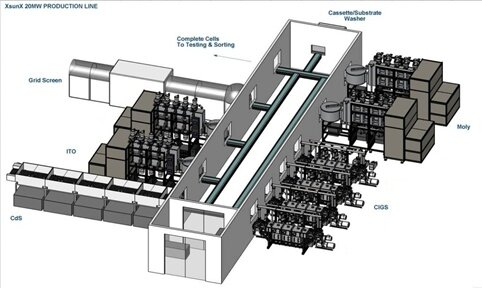

In conjunction with our proprietary CIGSolar® co-evaporation system, our design combines several mature technologies in use within the solar and semiconductors industries today. The resulting modular aspect of system components are scalable and can be clustered to support one or more CIGSolar® co-evaporators to meet your production requirements. There are seven distinct systems and steps worked into the flow line process:

The completed 156 mm square cells match typical silicon cell dimensions, and the non-breakable stainless steel substrates reduce downstream transport and assembly losses. The finished cells are interconnected similarly to the way silicon cells are tabbed and strung to produce modules. As a result, cell properties can be matched to improve yield and reduce loss and module rejects that can occur with monolithic assembly techniques.

If your plans require complete backend solar module assembly capabilities, XsunX can introduce industry proven 3rd party suppliers capable of providing tabbing stringers, laminators, and module testers to help complete your facility.